Our Handcrafted Straps

We believe that every watch deserves to be complemented with an equally remarkable counterpart - the strap.

Every Delugs strap is the culmination of thoughtful, painstaking steps in design and craftsmanship. The aim is enduring visual and physical quality for every strap that leaves our workshop.

We are proud to show you how each strap is transformed from its raw materials to its final form by our team of crafters, taking anywhere from 4 to 6 hours from start to finish.

Watch Our Leather Crafting in Action

From Start to Finish: Every Step

Step 1

Leather Selection

Everything starts with the leather, which we source from tanneries around the world.

Step 2

Material Preparation

Leather is cut into the rough shape and size needed to make the strap.

Step 3

Splitting

Leather is thinned down to the required thickness with the splitting machine.

Step 4

Logo Stamping

Logo and sizing information is stamped onto the lining.

Step 5

Reinforcement

A layer of reinforcement is added to the leather for additional durability, and to prevent stretch.

Step 6

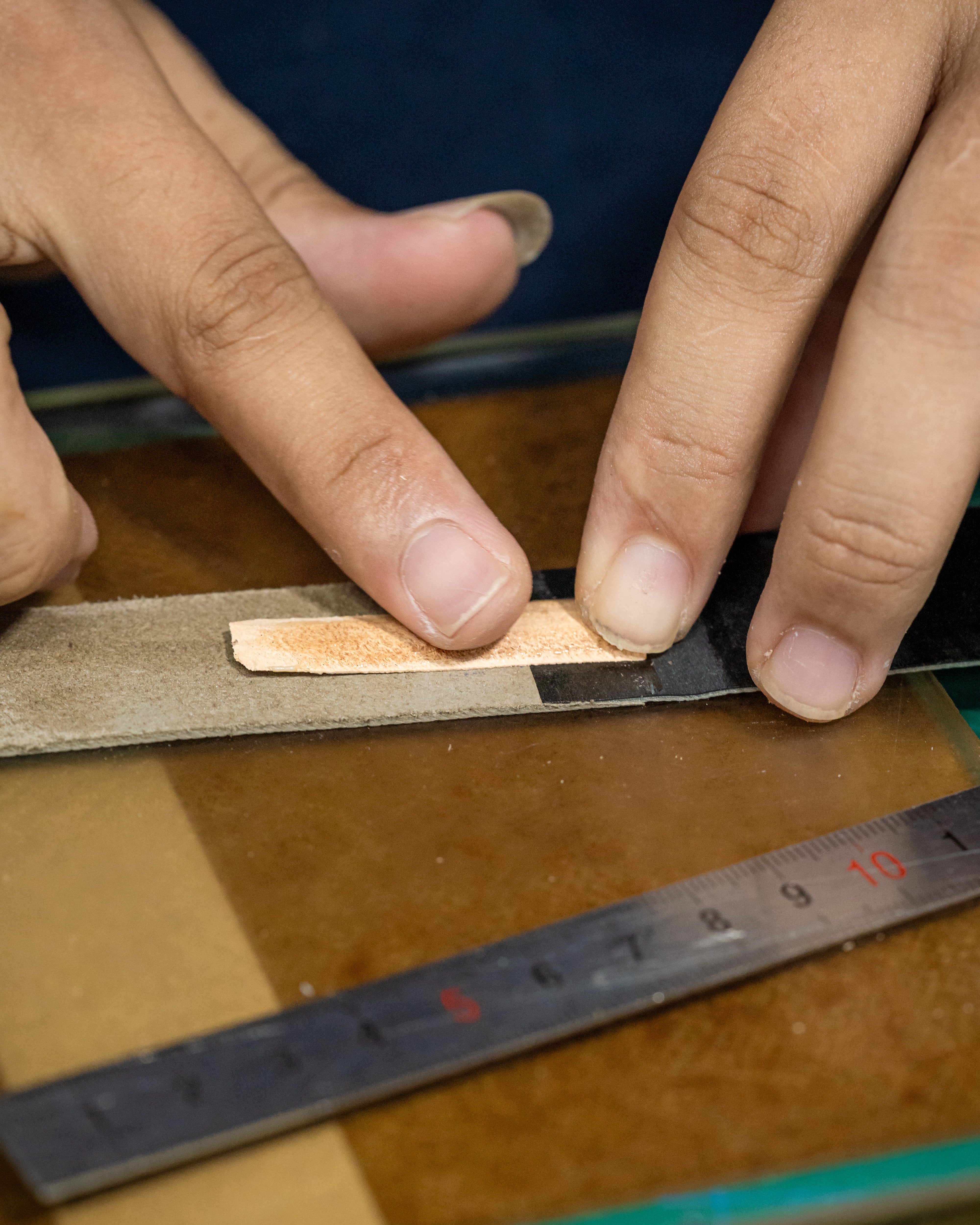

Skiving

The leather is thinned down at the ends, to allow for a seamless transition between the main and lining leather.

Step 7

Shaping Padding

A piece of leather is cut and shaped to form a dome, to be used as the inner padding.

Step 8

Assembly

The main leather with reinforcement layer, lining leather with logo stamped, and padding are all assembled and glued together.

Step 9

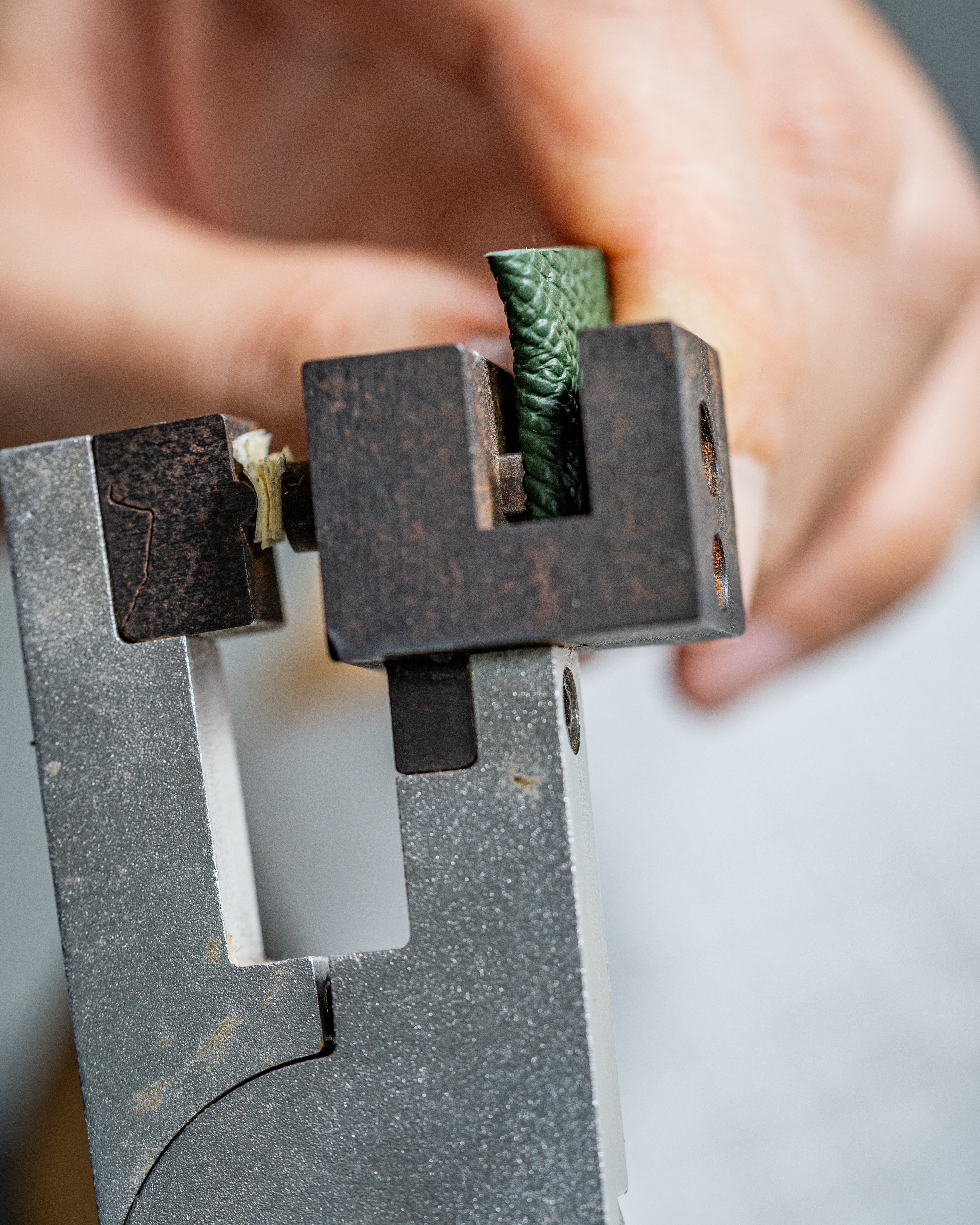

Clicking

The strap is cut into its precise shape with the help of a die press for standard sizes, or hand-cut for custom shapes and sizes.

Step 10

Pricking Holes

Holes for stitching are punched through the strap by a pricking iron.

Step 11

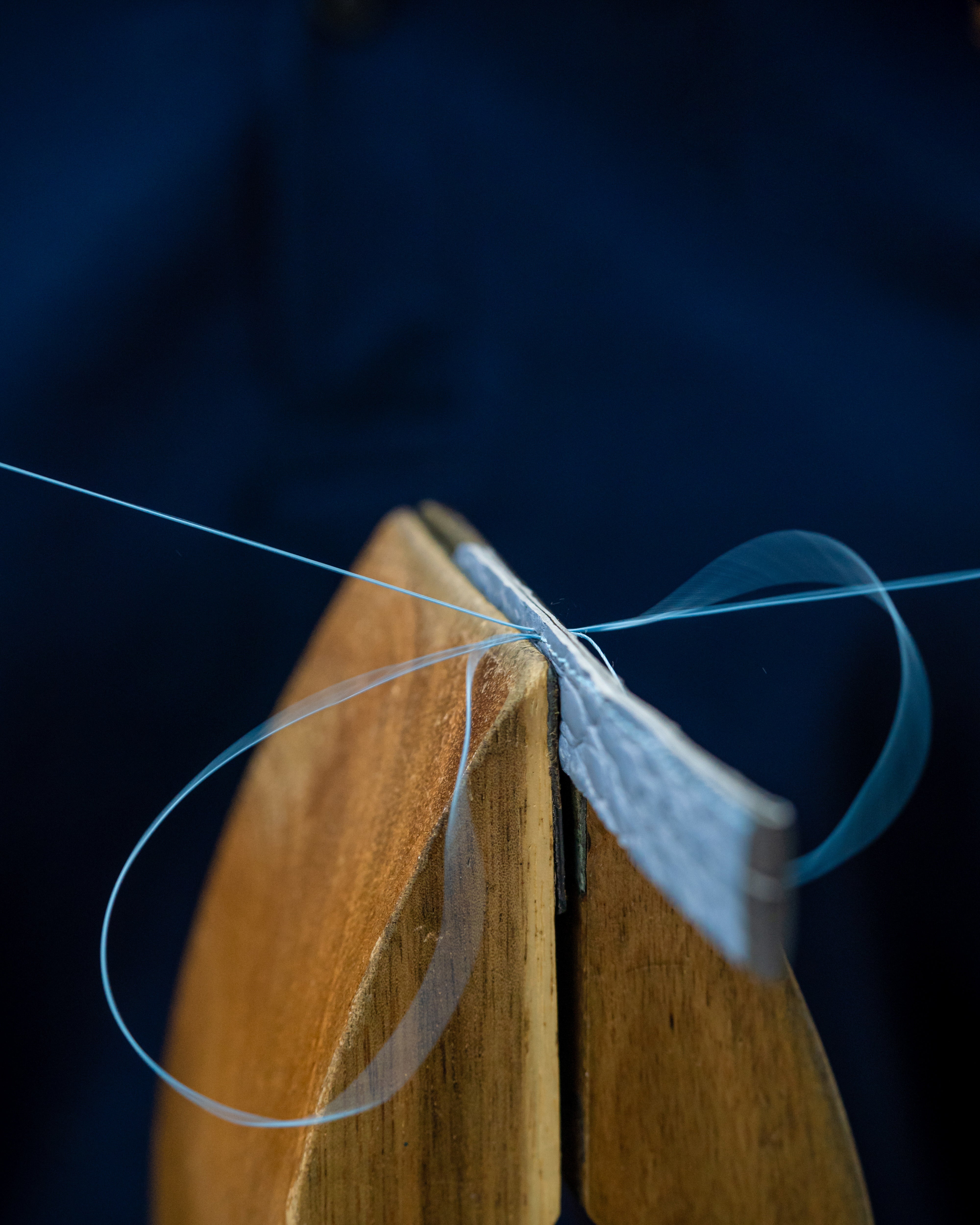

Saddle Stitching

Strap is stitched with the traditional saddle-stitching technique for greater durability.

Step 12

Edge Creasing

The front and back of the strap has a decorative line creased into the leather with the help of a heated fileteuse machine.

Step 13

Edge Finishing

A layer of paint is applied onto the sides of the strap to seal it up, and then sanded down for a smoother surface.

Step 14

Strap Keepers

Fixed and floating strap keepers are assembled and attached onto the strap.

Step 15

Punching Strap Holes

Strap holes are punched into the strap. Measure twice, punch once!

Step 16

Attaching Buckle

Buckle tongue notch is punched and the buckle is installed.

Step 17

Quick Release Spring Bars

A notch for the quick release spring bars is punched into the strap, and the spring bars are installed.

Step 18

Quality Control

Strap is checked to ensure that there are no flaws, marks, or defects, and that the measurements are precise and accurate.

![Anthracite Hook Strap [kollokium x Delugs]](http://delugs.com/cdn/shop/files/20250919-A7405309_298x298_crop_center.jpg?v=1761299094)

![Anthracite Hook Strap [kollokium x Delugs]](http://delugs.com/cdn/shop/files/Kollokium_straps_Anthracite_1_298x298_crop_center.jpg?v=1761299094)

Buy One, Get One 15% Off

Buy One, Get One 15% Off

![Baby Blue CTS Rubber Strap for IWC Ingenieur [Prototype]](http://delugs.com/cdn/shop/files/20251001-DSC02482_1_298x298_crop_center.jpg?v=1759730616)

![Baby Blue CTS Rubber Strap for IWC Ingenieur [Prototype]](http://delugs.com/cdn/shop/files/IWC_Ingenieur_Rubber_CTS_Baby_Blue_298x298_crop_center.jpg?v=1759303635)